crusher plant maintenance articles

Construction Working and Maintenance of Crushers for Crushing

Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article. Crushing Technology. There are four basic ways to

[خذ المزيد]

Maintenance of Aggregate Crushers Agg-Net

2017年9月8日 Performing regular maintenance on crushers is integral to the reliability, performance and output they achieve. Prevention is better than cure; by carrying out regular inspections operators will ensure that their crusher runs

[خذ المزيد]

Reliability centered maintenance of cone crusher: a case study

2014年2月25日 A cone crusher is used in mineral processing plant as a secondary or tertiary type rock crusher. In this case study, explored the general objective of the failure modes and

[خذ المزيد]

Reliability analysis of mining equipment: A case study of a

2008年4月1日 This paper presents a case study describing reliability and availability analysis of the crushing plant number 3 at Jajarm Bauxite Mine in Iran. In this study, the crushing plant

[خذ المزيد]

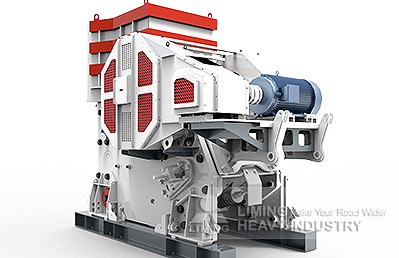

A Balanced Approach to Crusher Maintenance - For

2005年9月20日 Experienced crushing professionals offer their views on maintenance of horizontal impactor plants. Invest in quality, then maintain it

[خذ المزيد]

Crushing Plant Design and Layout Considerations - 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

[خذ المزيد]

Maintenance and Optimization of Crushing Plants: Enhancing

2023年9月2日 aintenance and optimization practices are key to the reliable operation and longevity of crushing plants. By implementing regular inspections, effective lubrication and fluid

[خذ المزيد]

Seven Critical Maintenance Items For Mobile Crushing Plants

2023年10月26日 The seven critical maintenance items discussed in this article, including lubrication systems, conveyor belts, crusher components, screening components, electrical

[خذ المزيد]

Avoid Unplanned Downtime: 5 Crusher

2019年2月5日 Too many companies don’t invest enough into their equipment maintenance, and ignoring maintenance issues doesn’t make the problems go away. “According to leading aggregate producers,

[خذ المزيد]

Construction Working and Maintenance of Crushers for Crushing

Efficiency of a multiple stage crushing plant can be maximized by operating a primary crusher at a setting which produces a satisfactory feed size for the secondary crusher and operating the secondary crusher (or the last stage crusher) in a closed circuit. Glossary of Terms Breaker Block (Breaker Plate)

[خذ المزيد]

Crusher maintenance tools - Metso

Metso lifting tools make the maintenance of your crusher easy, safe and more efficient. All of our lifting tools are backed by Metso quality, OEM design and expertise, making them the best choice to lift Metso

[خذ المزيد]

Crushing Plant Design and Layout Considerations - 911 Metallurgist

Crusher maintenance 78 1 concave change box 1, 2 months changes 24 x 2 Minor scheduled maintenance 0 Shift changes 183 10 minutes/shift Total ... Ore characteristics are a critical element in both crusher selection and plant design. Dry ores require greater provisions for dust suppression and collection, ...

[خذ المزيد]

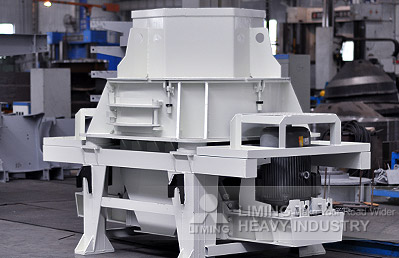

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023年2月28日 Learn how to choose, operate, and maintain a stone crusher plant with our comprehensive guide. Discover the different types of stone crusher plants, their environmental impact, maintenance requirements, and case studies of successful operations. Get answers to frequently asked questions and ensure the safety and

[خذ المزيد]

A Guide to Mobile Crushing Plants: Types, Components,

2023年2月24日 Regular cleaning of the mobile crushing plant, including the crusher and conveyor, can prevent buildup and ensure that the plant is operating at maximum efficiency. Proper storage: When the mobile crushing plant is not in use, it’s important to store it properly to protect it from the elements and prevent any damage.

[خذ المزيد]

Failure rate analysis of Jaw Crusher: a case study Sādhanā

2019年1月2日 Failure of crusher components has considerable influence on the productivity of a crushing plant. In order to improve performance and operational reliability, its critical components are needed to be identified to make replacement in time before any catastrophic failure happens. Though traditional maintenance practices exist in crushing

[خذ المزيد]

Crushers - All crusher types for your reduction needs - Metso

The main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt. In most crushing installations a jaw crusher takes care of primary crushing. Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher.

[خذ المزيد]

Optimization Framework for Crushing Plants Request PDF

2019年6月10日 Request PDF Optimization Framework for Crushing Plants Optimization is a decision-making process to utilize available resources efficiently. The use of optimization methods provide ...

[خذ المزيد]

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Choosing the right type of primary crusher for your operation depends on several factors, including the maximum size of the material to be crushed, the desired output size, and the capacity of the crusher. Other factors to consider include the hardness and abrasiveness of the material, as well as the cost and maintenance requirements of the ...

[خذ المزيد]

Crusher Plant Maintenance Pty Ltd LinkedIn

Crusher Plant Maintenance Pty Ltd 739 followers on LinkedIn. Crusher Plant Maintenance was established in 2009 servicing the mining, construction and quarrying industries and has now grown ...

[خذ المزيد]

Crushers Plant - SAR

Our dedicated customer support team provides comprehensive assistance, ensuring smooth installation, operation, and maintenance of our crusher plants. We strive to build long-term relationships with our clients and provide ongoing support to help them achieve their production goals. Whether it’s for mining, construction, ...

[خذ المزيد]

Primary Crusher vs. Secondary Crusher:

2023年2月28日 Granite Crushing Plant; Projects Menu Toggle. ... In this article, we will discuss the primary crusher and secondary crusher, their definitions, functions, and different types. We will also examine how they

[خذ المزيد]

Preventive crusher and screen maintenance - Metso

We got comments from Anthony Ryan, sales manager for McHale Plant Sales, based in Tipperary, Ireland, who says Metso Metrics is very useful for preventative plant maintenance and servicing. “We can predict when a plant service is needed, allowing us to better prepare our engineers.

[خذ المزيد]

The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

2023年2月23日 Primary considerations: Accessibility, safety, and maintenance are critical factors to consider when designing the layout of an aggregate crushing plant. This includes ensuring that there is adequate access for maintenance and repair work, that the plant is designed with safety in mind, and that maintenance is easy and efficient.

[خذ المزيد]

Demystifying the Crusher Plant: A Comprehensive Guide to

5 天之前 Crusher Plant Aggregate crushing operation is the process of dealing with and processing non-metallic mineral materials for the construction ... Because of the improved coordination, real-time data analysis, and predictive maintenance made possible by this link, dependability has increased and breakdowns have decreased. Energy ...

[خذ المزيد]

The Most Practical Jaw Crusher Repair and Maintenance Manual

2023年2月15日 For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production. It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance.

[خذ المزيد]

Understanding Cone Crusher Parts Names, Functions, and Maintenance

2023年2月22日 Description: This article provides a comprehensive guide to understanding the different parts of cone crushers, their functions, and the importance of proper maintenance. It covers various types of cone crusher parts, common issues and solutions, and future developments in the industry. Whether you are in the market for a new cone

[خذ المزيد]

Tips for Crusher Maintenance - Thomasnet

2019年1月27日 Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment. Every 40 hours, check for leaks and inspect Y strainers. Every month, inspect safety devices and perform an oil analysis. At least once per year (or every 2,000 hours) change all oil.

[خذ المزيد]

Understanding Jaw Crusher Parts and Their Functions - AGICO

2023年2月23日 Some fixed jaws have a smooth surface, while others have teeth or ridges to enhance their crushing performance. The size and shape of the fixed jaw also play a role in determining the capacity of the jaw crusher. Maintenance Tips: Proper maintenance of the fixed jaw is essential for ensuring the jaw crusher operates efficiently and effectively.

[خذ المزيد]- نوربيرغ المخروط المطحنة

- مقر ادارة المطاحن في حامة بوزيان

- لفة مزدوجة نوع محطم الشركات المصنعة محطم

- معدات تكسير البناء جنوب أفريقيا

- يمكن سحق فحم الكوك في طاحونة الكرة

- كسارة قذيفة الجوز

- كسارة تكسير فعالة

- عالية الكفاءة مطحنة الكرة مطحنة شعبية في أفريقيا وآسيا

- معدن در آفریقای جنوبی جنوب

- كسارات الحجر المحمول في السعودية الكاولين

- محطة التكسير الأولية المتنقلة م معتمدة

- كسارة متنقلة للبيع في كاليفورنيا

- كسارة العملية التجارية في الصين

- الكرة المخروطية endmill كربيد

- كسارة فحم متنقلة للإيجار في أنغولا

- خطط مطحنة طحن الأسطوانة

- مطحنة الحجر الأحجار الصناعية

- searation سنگ شکن آجر

- فک سنگ شکن میلیمتر قیمت

- وعيوب ومزايا التعدين الحديد

- دوارة آلة فحص الرمال في مصر

- تصاویری از کروم پردازش

- مباراة الفحم نوع طاحونة

- كسارة الحجارة 10 tph واحد تبديل النبات

- الجير حجر الأسطوانة الأسطوانة مطحنة

- طريقة طحن الكرة لتحضير المواد النانوية قوات الدفاع الشعبي

- در ایتالیا از ماشین آلات سنگ شکن سنگی استفاده شده است

- مخصص الحزام الناقل ماليزيا

- قیمت فک پایونیر

- دستگاه سنگ شکن چکش تجهیزات

© Copyright - PETER&X محطم